Fermentation & Alternative Protein Industry: Report Breakdown

Back in September, the Good Food Institute (GFI) released their State of the Industry Report on Fermentation. The report provides us with an in-depth analysis of the science, business and future of fermentation in the alternative protein industry.

Back in September, the Good Food Institute (GFI) released their State of the Industry Report on Fermentation, which you can find here. The report provides us with an in-depth analysis of the science, business and future of fermentation in the alternative protein industry. To accompany the report, the GFI held a virtual fermentation Symposium and our very own Science Manager and Fermentation Specialist, Rob Johnson, was invited along to present!

Here at Quorn Nutrition, we are determined to educate our Healthcare Professionals on the wonders of Quorn mycoprotein, and whilst fermentation may not be a household name yet, Quorn’s wonderful products rely on fermentation and fungi, making these topics close to our hearts! With that in mind, our Nutrition Analysis Intern, Zoe Hill, is here to give you a breakdown of the report.

Despite a long history of use in the food industry, fermentation has only recently emerged as a key player in the alternative protein world, and the amazing health and environmental benefits of the process remain unknown to many.

Did you know there are 3 different fermentation processes?

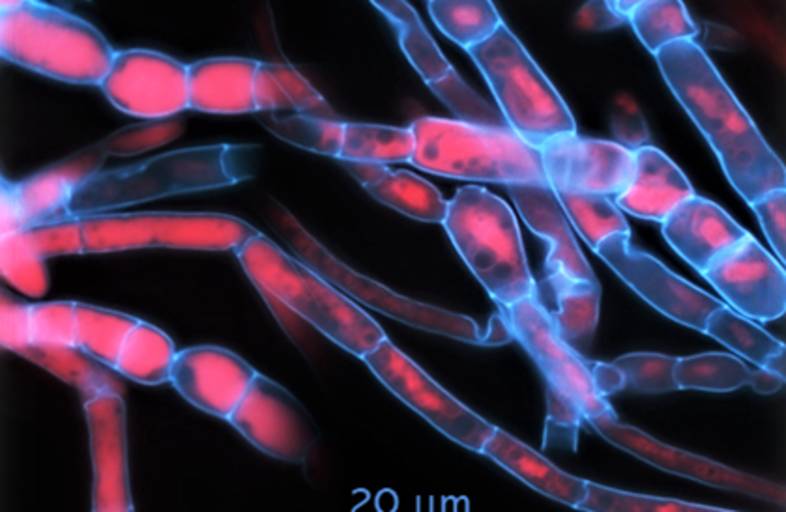

• Biomass fermentation (the process used to create Quorn products) which uses the high protein content and fast growth inherent to microorganisms to generate large quantities of protein;

• Traditional fermentation, which uses live microorganisms to transform and process plant-derived ingredients;

• Precision fermentation, which uses microbial hosts to manufacture cells and purify functional ingredients.

Here at Quorn Foods, we use biomass fermentation. This is a particularly efficient and scalable method. Compared to animals, microorganisms such as fungi have relatively short lifecycles – as little as a few minutes or hours in some cases, and each lifecycle provides an opportunity to double the available biomass. On a large scale, this means that tonnes of biomass or in our case, Quorn mycoprotein, can be created in a short period of time, all the while retaining the structural complexity of the end product.

The conceptual landscape of fermentation-derived and enabled products [Source: GFI SOTIR – Fermentation]

Fermentation of this nature produces a protein source that can meet the current, and rapidly increasing, demand and positively contribute to health on a global scale. Microbes are more efficient at converting calories to protein and high-value molecules than livestock, reducing land, water and pollutant usage as well as greenhouse gas emissions. Rob explains that when it comes to converting grain and other carbohydrates into protein:

“All animals are doing is concentrating what’s already there. We sidestep all that, we leave that protein available and then we add more.”

On top of all of this, our fermentation method replicates the taste and texture of animal products, unlike any other process. The end product is naturally high in key nutrients and has increased digestibility. Did you know that Quorn mycoprotein – the key ingredient in all Quorn products – is low in total and saturated fat, high in protein, high in fibre and contains no cholesterol! In the last year, research from the University of Exeter has shown Quorn mycoprotein’s superior capability to stimulate muscle growth compared to milk proteins and has been shown to reduce levels of LDL (‘bad’) cholesterol. You can read more about these studies here.

Most importantly, the growing body of evidence is correcting any misconceptions about the impact of fermentation. Rob highlighted how simple the process is:

“If you think about it, the vegetarian products are a white egg omelette with a mycelium fillet to give it some texture, so it’s quite a simple product with a clean label”.

Nonetheless, there is still a lot of ambiguity within the industry, but we are working on doing our part to help educate our Healthcare Professionals and to best inform their professional practice.

To find more about the fermenting of fungi and how Quorn products are made, have a read of our How Quorn mycoprotein is Made page. Now you’ve finished reading, don’t by shy! We want to know what you think – reach out to us on social @quorn_nutrition or email us at quornnutrition@quornfoods.com

This is just a snippet of the great event and report produced by the GFI so for more:

To download the full report: https://www.gfi.org/blog-fermentation-state-of-the-industry-report

To watch the recordings of the symposium:

https://www.youtube.com/playlist?list=PLaLco7qZryP5yBC6Cp3Yg-UUhN_jDOwqt